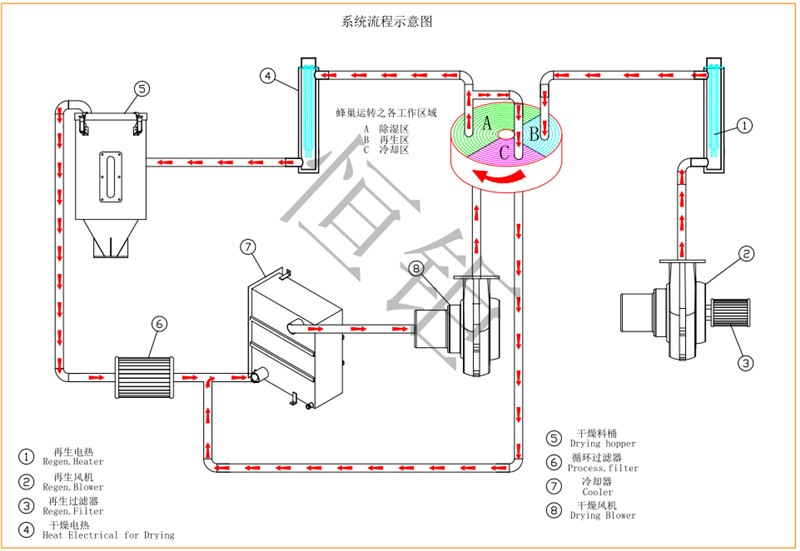

Working principle of three-machine integrated dehumidifier and dryer:

1. Dehumidification and drying part: the hot and humid air from the drying drum is cooled and blown into the honeycomb runner;The water in the air is absorbed by the wheel and then desorbed by the regenerative heated air.Two streams of air act on the wheel at the same time, and as the wheel rotates, the water in the air is continuously adsorbed and desorbed by the regenerated air and discharged, forming a stable low-dew point air.After heating to the drying temperature of plastic, it is blown into the drying drum to form a closed cycle and dry raw materials.

2. Suction part: The suction is sucked into the dry material bucket from the material storage barrel or other storage bin containers. When the vacuum hopper's magnetic spring switch detects no material, the suction motor runs to generate vacuum in the vacuum hopper.The raw materials in the storage barrel are sucked into the vacuum hopper due to the difference in air pressure. When the suction time is completed, the suction motor stops running and the raw materials will fall into the dry material barrel due to their own weight.The dried material is pumped from the drying drum to the electric eye hopper installed in the plastic forming machine.

Features:

1, set dehumidification, drying, two feeding three functions in one, and can choose a one-to-many system.

2. The dehumidifying part is equipped with a wheel device, which can provide low dew point air with good stability, and the dew point can reach below -40℃;

3, stainless steel double-layer heat preservation drying drum adopts downblown air pipe design, make raw materials evenly dry, and effectively prevent heat loss;

4. The feeding system is equipped with cutting valve to ensure that there is no residual raw material in the feeding tube;

5, the loop closed feeding system, can avoid raw materials pollution or moisture return;

6. Adopt high degree of automation, can choose touch control man-machine interface, internal use of programming controller Siemens PLC as the main control;

7. Optional dew point meter, convenient for monitoring dew point at any time;

8, optional suction box and automatic packing machine, easy to transport raw materials

9. When it is changed to conform to the safety loop type of European standard, "CE" shall be added after the type.

|